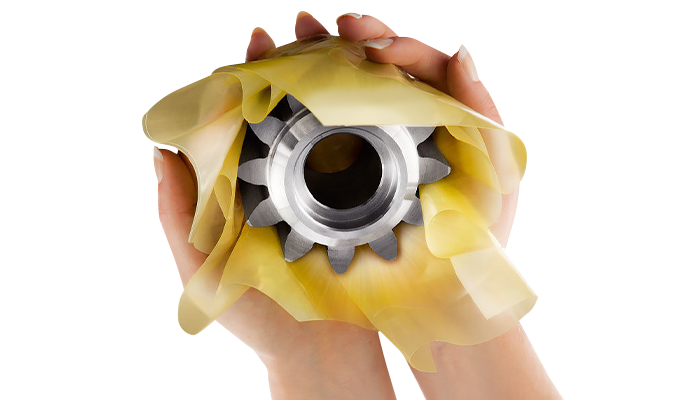

We provide end-to-end solutions - specialty coatings, cleaning compounds, VCI products and services. The diverse product line that we carry are manufactured at world class facilities backed by R&D.

Asset Integrity Management (AIM) – Our methodology for corrosion control and asset preservation projects during long cold layup and mothballing. AIM ensures selection of right corrosion control solutions, process approach, efficient application of cleaning and VCI packaging products and services delivery.